Choosing a third-party logistics (3PL) provider can be a transformative step for e-commerce sellers, but understanding the costs and fees involved is crucial for making informed decisions. 3PLs handle the storage, packing, and shipping of your orders, allowing you to focus on sales and growth while they streamline your operations.

However, their pricing structures can seem complex at first, with various fees and industry terms that might be unfamiliar. This comprehensive guide will demystify the common costs and fee structures associated with 3PL providers, so you can interpret quotes with confidence and avoid any surprises on your bills.

Note: This is an educational guide focused on understanding 3PL pricing generally. At Marketplace Valet, we believe in transparency and helping brands make informed decisions about their fulfillment strategies.

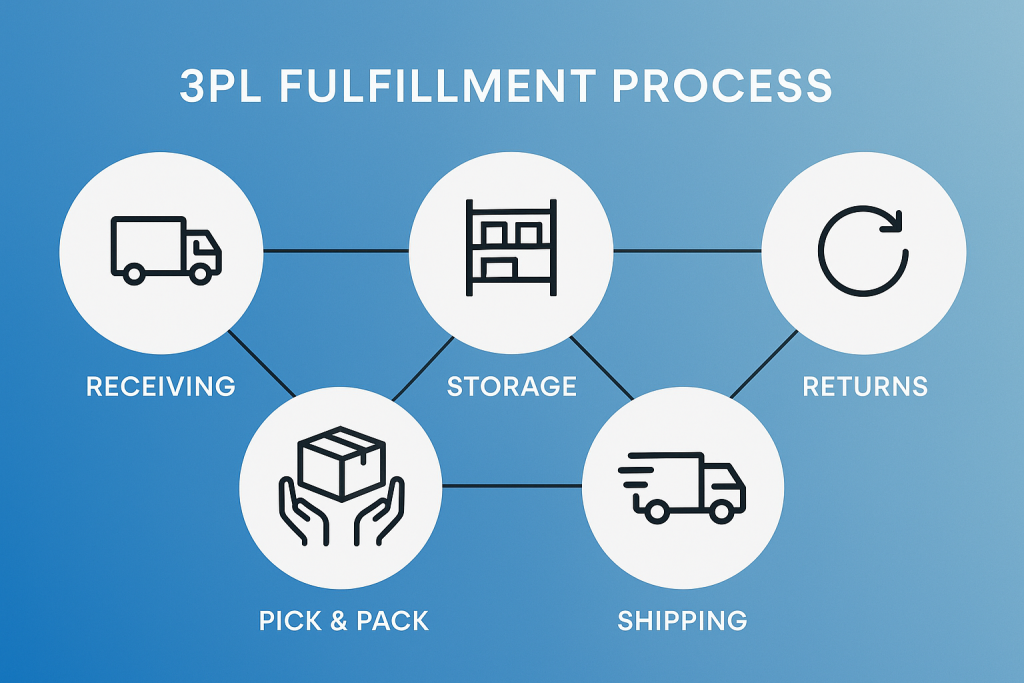

What Is a 3PL and How Do They Charge?

A 3PL (third-party logistics) provider is a company that offers outsourced logistics services, which often include warehousing, inventory management, picking and packing orders, shipping, and sometimes additional services like kitting or returns handling.

Essentially, a 3PL acts as your fulfillment partner: they store your products and take care of getting orders to your customers. In return, you pay them fees for the various services performed.

Activity-Based Pricing Model

Most 3PLs use activity-based pricing, meaning you are charged for each specific activity or service involved in fulfilling your orders. At the end of each billing cycle (often monthly), the 3PL will tally up all activities and issue an invoice.

Common 3PL Fee Categories

- Setup & Onboarding

- One-time charges for account setup and system integration

- Receiving Fees

- Charges for accepting and processing incoming inventory

- Storage Fees

- Monthly charges for storing products in the warehouse

- Pick & Pack

- Core fulfillment fees for picking and packing orders

- Shipping Costs

- Carrier fees passed through to customers

- Returns Processing

- Fees for handling returned merchandise

Typical 3PL Cost Breakdown

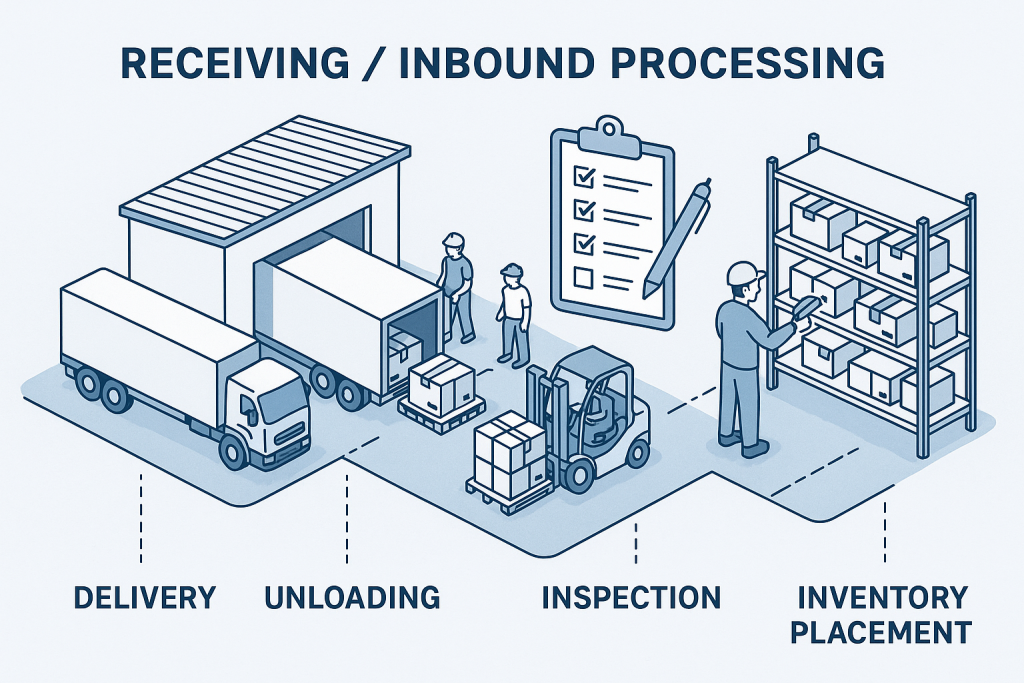

Receiving Fees (Inbound Processing)

What Are Receiving Fees?

Receiving fees are what you pay when your inventory arrives at the 3PL’s warehouse. This fee covers the labor and time required for warehouse staff to accept your shipment and prepare your products for storage.

The Receiving Process Includes:

- Unloading boxes or pallets

- Counting and verifying items

- Inspecting for damage

- Labeling units if needed

- Storing in warehouse locations

How Receiving Fees Are Charged

Per Pallet or Carton

Flat fee for each pallet or box received$5-$20 per pallet

Per Unit (Piece)

Fee for each individual item received$0.20-$2.00 per unit

Hourly Rate

Labor cost for processing shipments$25-$80 per hour

Per Container

Flat rate for full container shipments$300-$500 per container

Pro Tips for Managing Receiving Costs

- Communicate with suppliers to pack shipments according to 3PL guidelines

- Provide clear packing lists and proper barcodes

- Palletize products according to warehouse standards

- Clarify policies on handling discrepancies or non-compliant shipments

Storage Fees

Understanding Storage Fees

Once your products are on the warehouse shelves, storage fees start to accrue. These fees are charges for the space your products occupy in the 3PL’s facility – essentially like paying rent for storing your goods.

Important Cost Consideration

Storage often comprises around 50% of a 3PL bill on average, making it one of the most significant costs to manage effectively.

Common Storage Fee Models

Per Pallet Per Month

Fixed monthly rate for each pallet stored$15-$40 per pallet/month

Per Cubic Foot

Charging by volume your goods occupy$0.45-$0.55 per cu ft/month

Per Bin or Shelf

Monthly fee per bin or shelf space used$3-$6 per bin/month

Optimize Your Storage Costs

- Use forecasting to send only needed stock for the near term

- Monitor inventory turnover rates regularly

- Plan promotions for slow-moving inventory

- Understand any climate control or specialty storage premiums

Pick & Pack Fees

The Core Fulfillment Service

Pick and Pack is the core service of any fulfillment center. It refers to picking items from storage for an order and packing them securely for shipment. Every time an order comes in, warehouse staff will pick the ordered items and pack them with appropriate protection.

Industry Benchmarks (2025)

Average B2C Order:$3.25

Range:$0.50 – $5.00+

Typical Structure:$2-3 base + $0.50/item

Pick & Pack Fee Structures

Per Order Fee

Flat rate per order regardless of items

Example: $3.00 per order (assumes 1-2 items)

Per Item Fee

Fee for each item picked and packed

Example: $1.00 per item (3 items = $3.00)

Hybrid Model (Most Common)

Base fee + additional item charges

Example: $2.00 first item + $0.50 each additional

1 item = $2.00, 2 items = $2.50, 3 items = $3.00

What’s Included in Pick & Pack?

Always Included:

Labor to pick items and pack orders, shipping label application

Sometimes Included:

Box, packing materials, packing slips, marketing inserts

Often Separate:

Packaging materials ($0.50-$0.80), custom inserts ($0.15-$0.30)

Watch Out For Low-Ball Pricing

If a 3PL advertises very low pick and pack fees, look closely at other charges. Some providers offset low order fees with higher packaging charges or storage fees to make up the difference.

Shipping Costs (Outbound Freight)

Understanding Shipping Costs

After an order is packed, it needs to get to your customer via carriers like UPS, FedEx, USPS, etc. Shipping costs are usually passed through from the 3PL to you, meaning you’ll ultimately pay the carrier fee for each shipment.

Bulk Shipping Discounts

Most 3PLs have carrier accounts and can offer 10-30% discounts off standard carrier rates thanks to their high shipping volume. This can save you money compared to retail shipping costs.

3PL Shipping Pricing Models

62%

Cost-Plus Model

Add 5-10% markup on carrier rates

24%

Discount Model

Pass through discounted rates directly

14%

Your Account

Use your own carrier accounts (may incur handling fees)

Key Shipping Considerations

Zone and Weight Impact

Shipping costs depend on package weight, dimensions, destination zone, and service speed. Multiple warehouse locations can help reduce zone costs.

Carrier Surcharges

Fuel surcharges, residential delivery fees, and peak season surcharges will be reflected in your shipping charges.

Automatic Optimization

Advanced 3PLs use software to automatically select the cheapest carrier and service for each package.

Pro Tip: Total Cost Analysis

When comparing 3PLs, evaluate total fulfillment cost. A provider with slightly lower pick fees but higher shipping rates might end up more expensive than one with higher pick fees but excellent shipping discounts

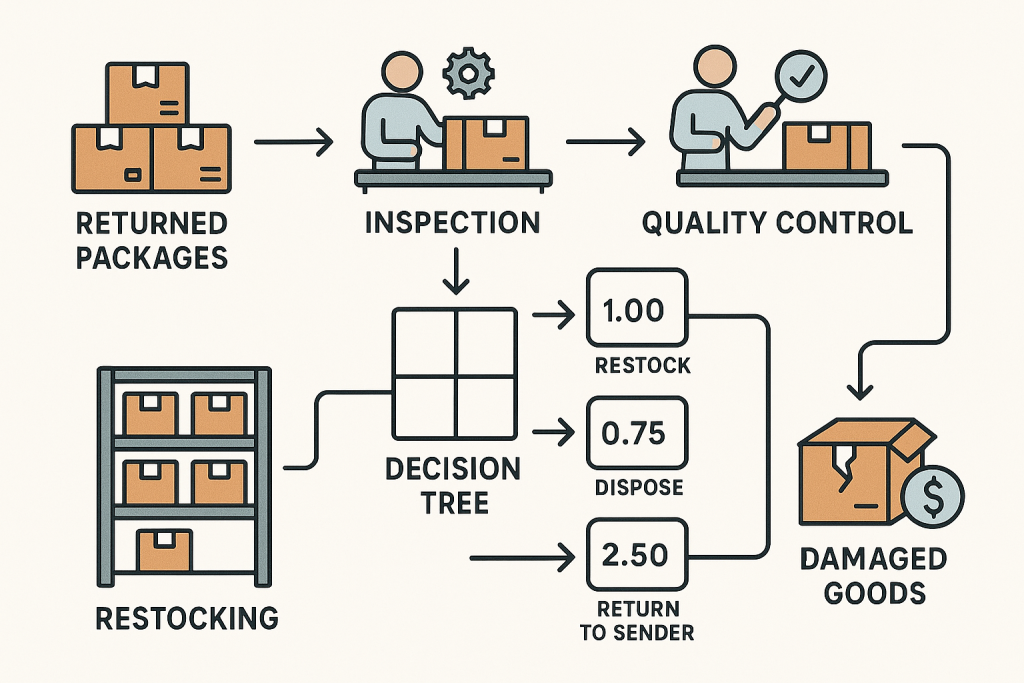

Returns Processing Fees (Reverse Logistics)

The Returns Process

In e-commerce, returns are inevitable. If customers send returns to your 3PL, you should understand return processing fees. This covers the work when an item comes back from a customer.

What Happens During Returns Processing:

- Receive and open returned package

- Compare items against RMA or packing slip

- Assess item condition

- Restock if resalable or mark as damaged

- Update inventory records

Returns Fee Structure

Industry Range

$1-$6 per return

Per Return Shipment

Flat fee regardless of items$2.00-$4.00

Per Item Returned

Fee for each item processed$1.00-$3.00

Cost Impact Example

If 5% of your orders come back as returns and each return costs $3 to process, that’s an extra $0.15 cost per order on average to factor into your pricing.

Optimizing Returns Management

- Fast processing enhances customer satisfaction

- Quick restocking helps recoup value from returned merchandise

- Clear quality assessment prevents damaged goods from being resold

- Prompt notifications help track return reasons and trends

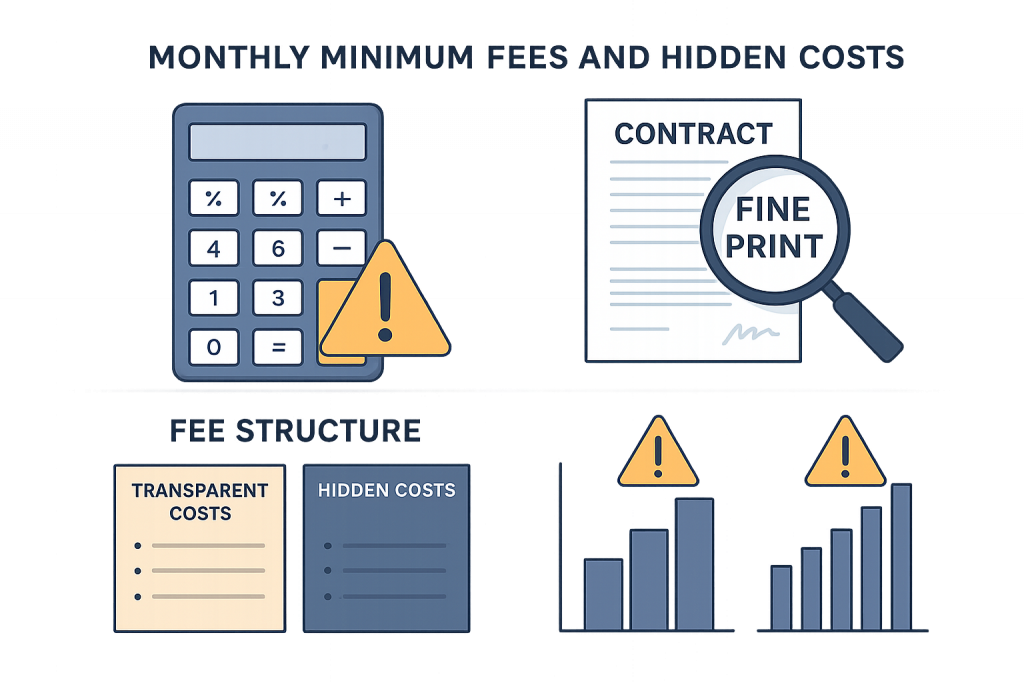

Monthly Minimums and Other Fees to Watch For

Monthly Minimum Fees

Some fulfillment centers require a minimum monthly billing or order volume. If your total fees don’t reach a certain amount, they’ll charge you up to that minimum.

Common Minimum Structures:

- Low-tier minimums:$1,000/month

- Mid-tier minimums:$5,000/month

- High-tier minimums:$10,000+/month

No-Minimum Providers

Many providers that cater to startups and small businesses advertise no minimum order requirements or no monthly minimum fees. This flexibility is crucial when starting out with low volume.

At Marketplace Valet, we believe in supporting growing brands with flexible terms that scale with your business.

Other Miscellaneous Fees

Setup/Onboarding Fees

One-time charges for account setup and integration$150-$1,500+

Kitting/Assembly Fees

Special projects like bundling or subscription box assembly$30-$50/hour

Special Handling

Dangerous goods, expiration tracking, quality inspectionsVaries by service

Long-Term Storage

Extra charges for inventory stored over 6-12 monthsPremium rates

Prep Services

Labeling, poly bagging, Amazon FBA compliancePer unit charges

Disposal/Removal

Disposing unsellable inventory or returning to youHourly or per item

Example: 3PL Cost Breakdown for a Small Online Seller

Scenario: Small Home Goods Retailer

Shipped 2 pallets of new inventory

Average 5 pallets stored throughout month

Fulfilled 100 orders (2 items average)

Processed 5 returns

$500 monthly minimum requirement

Key Insights from Example

Multiple Fees Add Up

Even small individual fees combine into significant monthly costs. Understanding each component helps with budgeting.

Minimum Fee Impact

The $500 minimum turned a $435 calculated bill into $500 – an extra $65 for not hitting volume threshold.

Scaling Benefits

As volume increases, cost per order typically decreases, and minimums become less impactful.

Monthly Invoice Breakdown

|

Fee Category |

Rate |

Cost |

|

Receiving (2 pallets) |

$10.00/pallet |

$20.00 |

|

Storage (5 pallets) |

$20.00/pallet/month |

$100.00 |

|

Pick & Pack (100 orders) |

$2.00 + $0.50/extra item |

$250.00 |

|

Packaging Materials |

$0.50/order |

$50.00 |

|

Returns Processing |

$3.00/return |

$15.00 |

|

Subtotal (Calculated Fees) |

– |

$435.00 |

|

Minimum Fee Adjustment |

$500 minimum |

+$65.00 |

|

Total Monthly Invoice |

– |

$500.00 |

Cost Per Order:$5.00

$500 total ÷ 100 orders = $5.00 per order

Tips for Comparing 3PL Quotes and Asking the Right Questions

Essential Questions to Ask

Quote Breakdown

“Can you provide a detailed breakdown of all fees including receiving, storage, pick/pack, and any additional charges?”

Inclusions vs. Extras

“Does your pick/pack fee include packaging materials, or are those charged separately? What about packing slips and inserts?”

Minimums & Contracts

“Is there a monthly minimum fee or order volume requirement? What are your contract terms and flexibility?”

Scalability

“Do you offer volume discounts? How often do you increase fees, and what’s your policy on rate changes?”

Evaluation Best Practices

Calculate Total Cost

Use your expected volumes to calculate total monthly costs across all providers for true comparison

Look for Hidden Fees

Watch for peak season surcharges, long-term storage fees, or fine print charges

Check References

Ask to speak with current clients and look for industry awards or recognition

Negotiate Reasonably

Setup fees and minimums may be flexible, but focus on operational fees you control

Value Over Price

Consider technology, reliability, and service quality, not just the lowest quote

Red Flags to Avoid

- Extremely low quotes without detailed breakdowns

- Unwillingness to provide references or transparency

- Long-term contracts with no flexibility for new businesses

- Hidden fees that only appear in fine print

Partner with Marketplace Valet for Transparent, Performance-Driven Fulfillment

At Marketplace Valet, we believe in transparent pricing and performance-driven results. Our comprehensive e-commerce solutions are designed to help your brand thrive while maintaining cost efficiency and operational excellence.

Transparent Pricing

No hidden fees or surprise charges – you know exactly what you’re paying for

Performance-Driven

Every dollar invested is backed by data-driven strategies for maximum ROI

Scalable Solutions

From startup to enterprise, we grow with your business needs

Ready to Optimize Your Fulfillment Strategy?

Use this guide to evaluate potential 3PL partners and make informed decisions about your fulfillment strategy. Remember, the goal is finding the right fit for your business, not just the cheapest option.

Price is what you pay. Value is what you get.